As you bask in the summer sun with the buzz of bees and bugs about, just relax with the thought that any one of those small creatures could actually be a miniature, pop-up insect manufactured at one of the world’s leading robotics development labs. “Do they suck blood??” you ask? No, no, no. That would be ridiculous. Not yet, but we do imagine that a swarm of them on your face would make for interesting conversation. The Microrobotics Lab at Harvard has developed a manufacturing process that makes mass-producing the winged wisps extremely quick and how they come together is even more fascinating.

Pop-Up Microbots

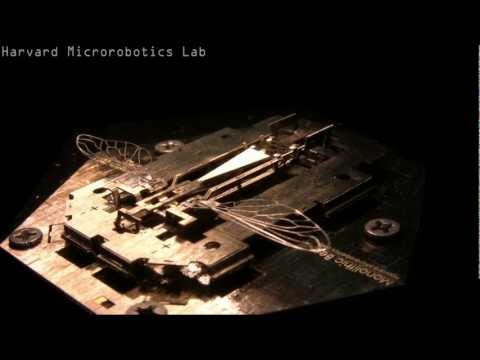

The Monolithic Bee, called the ‘Mobee’, is a small, millimeter-scale flying bot produced using Printed Circuit MEMS (PC-MEMS) techniques. This technique uses laser-cutting to construct the structure and support frame of the robot into various layers of structural material and adhesive. The layers combine to form the mechanics of the machine that can be created to quickly assembly in the same way a scene in a pop-up book comes together.

After fabrication, the resulting multilayer mechanical structures have intricate in-plane features, but remain flat with limited out-of-plane complexity. This restriction is widespread throughout MEMS; techniques to create truly three dimensional structures include vastly increasing layer number (3D printing), assembly through origami folding, and various self-assembly techniques. We take an origami folding approach to assemble three dimensional machines from flat multilayer laminates using a single ‘pop-up’ degree of freedom.

– Monolithic fabrication of millimeter-scale machines

Via Gizmag. Thanks Ion!